How Engineering Innovations Are Shaping Sustainable Commercial Buildings in Costa Rica

Summary

- The future of Costa Rican commerce is being engineered, not just built.

- Cutting-edge bioclimatic principles are replacing outdated reliance on energy-intensive air conditioning.

- Smart infrastructure, including BEMS and water recycling, drives operational costs down and efficiency up.

- The strategic use of local, low-carbon materials is tackling the critical issue of embodied carbon.

- Sustainable engineering now delivers the highest return on investment, setting a new global standard for the tropical commercial sector.

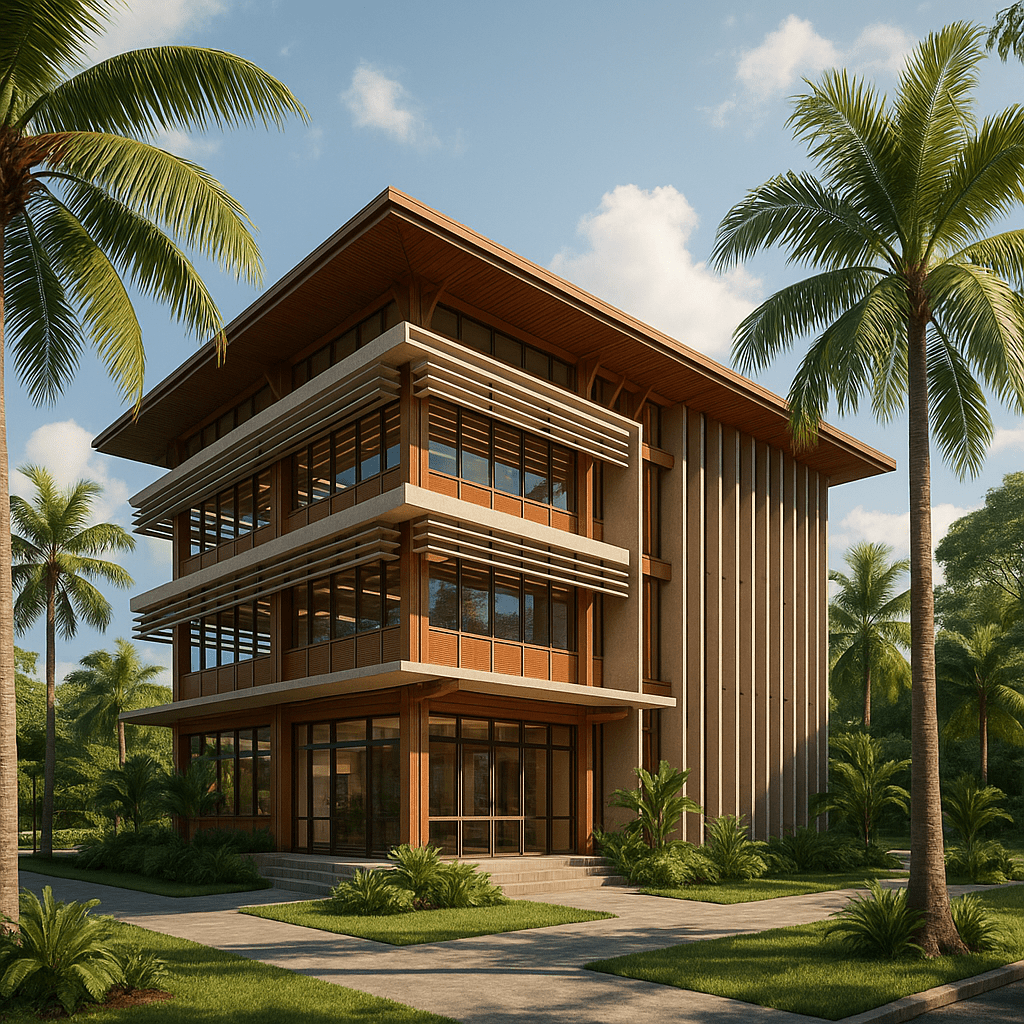

Beyond Green Paint: The Rise of Bioclimatic Engineering

For years, “green building” was a checklist of add-ons. Today, in Costa Rica’s commercial sector, it’s an integrated engineering discipline. Bioclimatic engineering is at the forefront of this movement, focusing on adapting the building’s form to the local climate from day one. This proactive approach drastically reduces reliance on mechanical systems.

- Optimal Orientation: Commercial structures are being meticulously positioned on the site to minimize direct solar heat gain on the long facades (East/West) while maximizing natural daylight (North/South). This simple strategy can reduce cooling loads by over 20%.

- Shading Elements: We design with brise-soleils, deep eaves, and integrated architectural fins to block the intense tropical sun before it hits the glass. This is passive engineering at its best, preventing heat transfer and maintaining comfortable indoor temperatures without using a single watt of electricity.

I’ve worked on office parks where the initial energy modeling predicted an enormous cooling demand, but by applying these bioclimatic principles—like using strategic shading and maximizing natural ventilation—we were able to design a system that was half the original size, saving the client significant capital and long-term operating expenses. This is the power of design driven by scientific data.

The Natural Air Conditioner: Passive Ventilation Systems

Air conditioning is the single biggest energy consumer in commercial buildings in the tropics. The engineering innovation here is to design buildings that breathe. We employ sophisticated cross-ventilation and stack-effect strategies.

- Operable Facades: Modern commercial buildings use intelligently designed, operable windows and louver systems that allow prevailing breezes to pass through the space.

- Thermal Chimneys: In taller structures, the central atrium or stairwell is designed to act as a thermal chimney. Hot air naturally rises and escapes through vents at the top, drawing cooler air in from lower levels. This creates a constant, gentle, and free flow of air.

This is fundamentally about creating a comfortable, healthy environment. Spaces with natural ventilation and non-toxic materials promote healthier environments, a key factor for modern tenants.

Smart Infrastructure: Technology for Resource Optimization

The sustainable commercial building of the future is not just passive; it’s smart and hyper-efficient. Engineering innovations in sensing and data analytics allow us to operate buildings with precision that was impossible a decade ago.

- Building Energy Management Systems (BEMS): These centralized systems monitor every aspect of a building’s energy consumption—from lighting to HVAC. They learn occupant patterns and adjust settings dynamically. If a meeting room is unoccupied, the BEMS automatically dims the lights and adjusts the temperature. This is crucial for achieving net-zero operational goals.

- Water Recycling and Management: Given the increasing stress on water resources, commercial buildings are pioneering closed-loop water systems. This includes rainwater harvesting for irrigation and toilet flushing, and greywater recycling systems that treat sink and shower water for non-potable uses. This reduces the building’s demand on municipal water by up to 40%.

This blend of passive and active technology is the key to maximizing both sustainability and tenant comfort. To delve deeper into how we integrate technology into our projects, explore our Our Sustainable Commercial Portfolio.

The Seismic-Sustainable Synthesis

Costa Rica’s seismic reality means that all engineering must prioritize structural resilience. Modern sustainable design addresses this by utilizing innovative materials that are both eco-friendly and structurally robust.

- Engineered Wood and Bamboo: These materials are renewable, store carbon, and offer excellent strength-to-weight ratios. Buildings using engineered timber and bamboo systems can often be built lighter than traditional concrete, which is advantageous for seismic performance.

Low-Carbon Concrete: We are seeing increased use of eco-friendly cement mixtures and concrete that incorporates recycled fly ash or slag. This significantly cuts the carbon footprint of the structure without compromising the essential structural integrity required by the rigorous Código Sísmico de Costa Rica (Seismic Code of Costa Rica). The integration of sustainability into the essential structure is a testament to the industry’s maturation.

Materials and the Circular Economy: Closing the Loop

The sustainability of a commercial building is determined long before its operation begins—it’s determined by the embodied carbon of its materials. Engineering strategies in Costa Rica are now focused on reducing this footprint through local sourcing and circular economy principles.

- Local Sourcing: Prioritizing materials from local suppliers drastically reduces transportation emissions. We work with local artisans and producers to source stone, wood, and aggregates, which also supports the local economy.

- Modular and Prefabricated Systems: The use of precast concrete panels or engineered modular units manufactured off-site reduces construction time, minimizes on-site waste, and ensures greater quality control. This approach is central to the shift toward a circular economy in construction—reusing, repurposing, and recycling materials rather than discarding them after a single use. The United Nations has highlighted the importance of this shift in Latin America; you can read more about it in their work on Green Building in Latin America.

This focus on the supply chain is critical because, as the construction sector is a major consumer of resources and producer of waste, innovative engineering at this level delivers the largest environmental savings.

Case Study: The Curridabat Corporate Campus

Consider the recent development of a corporate campus in Curridabat. The challenge was to create a high-density, Class-A office space that could still meet stringent environmental certifications (like LEED or RESET).

The solution was a fully integrated engineering approach:

- Challenge: High energy use is typical of large office spaces in the tropics.

- Engineering Solution: Implemented a chilled-beam cooling system—an innovation that uses water instead of air to cool the building, which is significantly more energy-efficient. This was paired with the automated BEMS and external solar shading.

- Challenge: Water consumption and stormwater runoff.

- Engineering Solution: Designed a rainwater harvesting system with a 100,000-gallon capacity integrated into the foundation. This water supplies the campus’s extensive green roof, vertical gardens, and non-potable uses.

- Challenge: Tenant comfort and air quality.

- Engineering Solution: Installed CO2 sensors in every zone, automatically increasing fresh air intake when levels rise. This ensures superior indoor environmental quality, directly correlating with improved employee health and productivity.

The outcome has been a stunning success: the campus operates at 45% less energy than the national commercial building average, achieved LEED Gold certification, and has seen superior tenant retention due to its exceptional air quality and comfort. For developers planning a project of this scale, understanding the regulatory landscape is key; we offer a full breakdown in our guide on Navigating Costa Rica Building Permits.

Conclusion: The Future is Engineered

The future of commercial development in Costa Rica is not defined by architectural height, but by engineering intelligence. Our competitive edge lies in leveraging bioclimatic science, smart technologies, and circular economy principles to build structures that are high-performing, resilient, and deeply sustainable. For homeowners and developers, embracing these engineering innovations is the surest path to creating value, reducing risk, and making a genuine contribution to Costa Rica’s green legacy.

Ready to future-proof your investment and build a commercial space that aligns with the highest global standards for sustainability and efficiency? Contact Architect Engineer today to schedule a consultation and begin the blueprint for your high-performance project. Let’s engineer the future of Costa Rica, together.

FAQ Section

Q1: What are the main advantages of bioclimatic engineering for a commercial building in Costa Rica?

A: The main advantages include a significant reduction in operational energy costs (often 30-50%) due to minimized reliance on air conditioning, improved thermal comfort and air quality for occupants, and increased property value due to sustainability certifications.

Q2: How does Costa Rica’s seismic code influence sustainable material choices?

A: While the code requires structural resilience, it doesn’t prohibit sustainable materials. Architects and engineers must demonstrate that materials like engineered wood or low-carbon concrete meet or exceed the strict seismic strength and flexibility requirements, leading to innovative composite structural systems.

Q3: Is a commercial building with a BEMS more complex to operate?

A: Initially, yes, setup is more complex, but a well-designed BEMS is built for simplicity. It centralizes control, automating tasks like light dimming and temperature setting, which ultimately makes the building easier and more efficient to operate than a traditional system over the long term.

Q4: What is the initial cost premium for a sustainable commercial building in Costa Rica?

A: The cost premium for a certified green building (like LEED or EDGE) typically ranges from 3% to 10% initially. However, studies show that the payback period for these costs is often less than five years due to substantial savings in energy and water.

Q5: What are Costa Rica’s main sustainability goals for the construction sector?

A: Costa Rica has set ambitious Decarbonization Plan goals, aiming for all new buildings to incorporate low-emission designs by 2030 and striving for the entire construction sector to be fully electrified and resource-efficient by 2050.